SUSTAINABILITY

The solar business is all about sustainability: and so are we.

We believe it really is possible to do well by doing good – and we’re proving it every day, through our fluoro-free, fully recyclable backsheets – now being used by module manufacturers around the world.

More than one million solar modules are installed every day. When these modules reach their end-of-life in 20-30 years’ time, that equates to 800 tons of landfill waste every day.

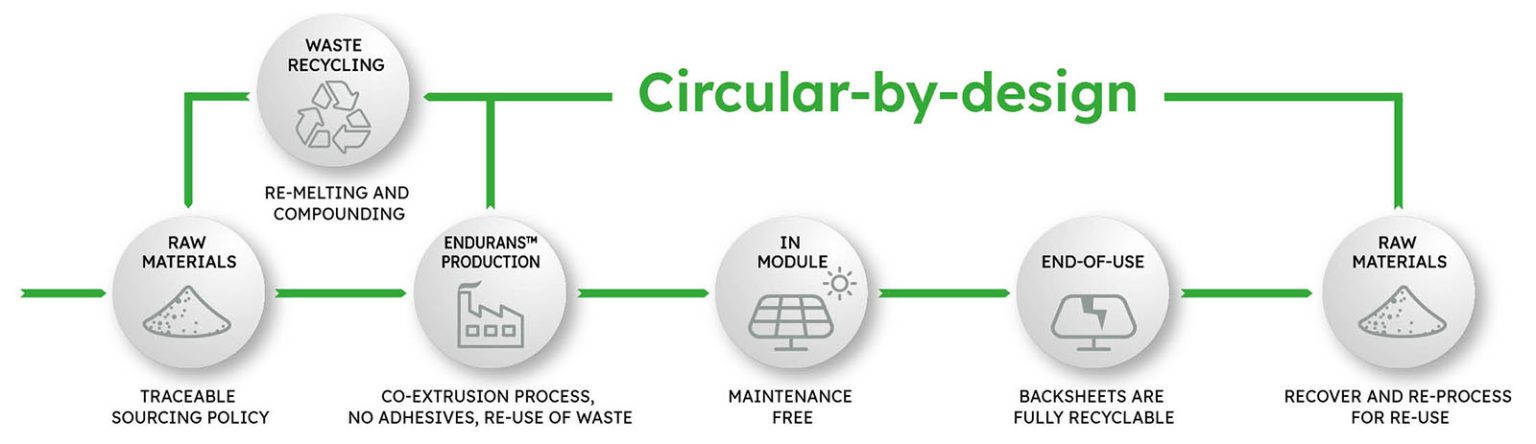

This challenge drove us to create the high-performance co-extruded backsheet Endurans® HP. After all, what’s the point in solving one of our world’s defining challenges (the provision of clean energy) only to create another one (the needless waste of valuable resources)?

We need to start designing our solar modules in a more circular way, right now.....

Solar modules installed every day

SOLAR PANELS REACHING END OF LIFE

BACKSHEET WASTE EVERY DAY

A sustainable solar industry means creating modules from circular materials & components.

Fluoro-polymers are used in many backsheets today to protect the weak PET core layer. These fluoro components are toxic for the environment and expensive to process at end-of-life.

Endurans® HP solves this problem because it’s designed for a circular future. Our backsheets are made from traceable materials with a low carbon footprint. They are toxin free; and they’re fully recyclable at end-of-life. In fact, we’re already recycling the waste generated in our manufacturing process.

The first carbon (near) net zero backsheet

Endurans® HP backsheets have a near net zero cradle-to-cradle carbon footprint, because of their low carbon emissions in production and an efficient waste-to-feedstock end-of-life treatment. This is out of reach for traditional coated or laminated CPC and KPf backsheets.

Based on its lowest carbon footprint per square meter AND per kWh, Endurans® HP backsheet offers an excellent starting position to secure institutional or governmental tenders.